Cyclic testing involves different conditions (i.e. Dry, Salt Fog, Salt Spray, Immersion, Cold and many more) over a period of time in a chamber allowing more transitions to better simulate environmental conditions.

Cycle steps include:

- High Humidity

- Dry

- Ambient

- Dwell

- Controlled Humidity

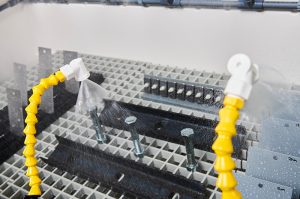

- Solution Spray

- Solution Fog

- Immersion

- Cold -20C

- High heat 90C

There are many OEM specifications that dictate the cycle as well as the type of solution (normally a complex mix of different corrosive agents.)

- GMW14872 Cyclic Corrosion Laboratory Test

- GMW3172 General Specification for Electrical/Electronic Components

- SAE J2334 Laboratory Cyclic Corrosion Test

- Ford CETP 00.00 L-467 Global Laboratory Accelerated Cyclic Corrosion Test

- Honda CCT

- Tesla Testing Standards

- Volvo 423-0014 Accelerated corrosion test

- VDA 233-102 Cyclic corrosion testing of materials and components in automotive construction

- Toyota TSH 1555G Test Method for Accelerated Corrosion under Complex Environment

With one call our experts can help you through this process and offer you the widest variety of chamber sizes to fit your needs. We have chambers that range for m 1400 cubic feet (6 feet long x 12 feet wide x 7 feet high) to 20 cubic feet to handle almost any size sample! No one on the planet has the variety testing space offered at ATC Test Lab!

Testing Certificate # 2563.02

Our lab is accredited by A2LA.Scope

A2LA Letter of Accreditation (PDF)

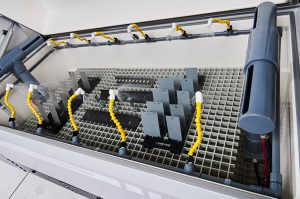

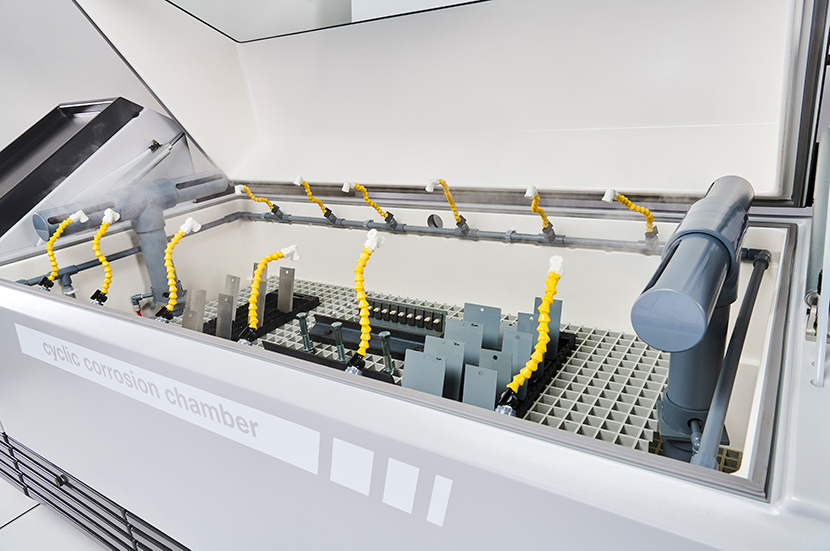

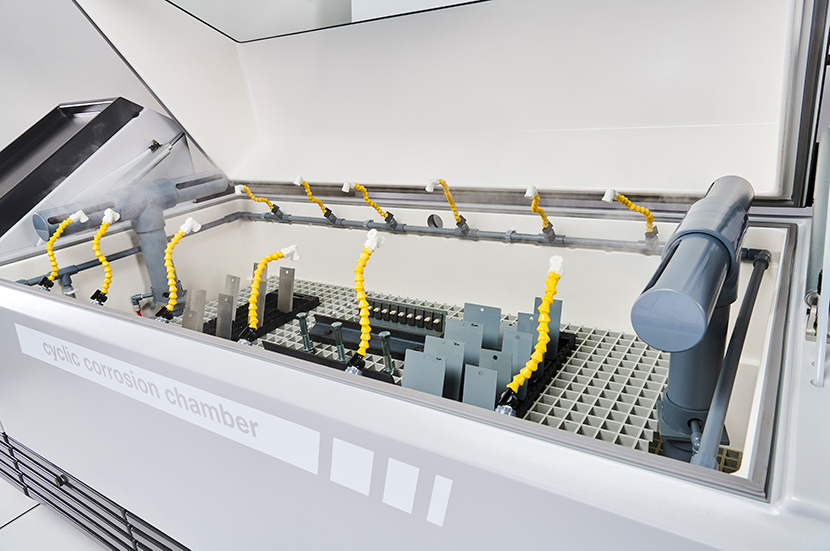

Cyclic Corrosion Test Chamber

Benefits of ATC Test Lab

A2LA Accredited Test Lab

Many manufacturers want to avoid hiring an accredited professional to conduct their sophisticated testing. By contracting ATC Test Lab you can avoid hiring and training costly specialized employees and equipment to conduct an array of tests.

Our experienced Laboratory Technicians understand the nature of each test, including GMW 14872. They are able to quickly detect product failure or unusual corrosion.

Specialized Testing Equipment and Chambers

ATC has new state of the art equipment to perform the most advanced testing. We have over 1200 Cubic Feet of testing space available, and the largest testing chambers in the world.

By contracting us, you can save money on new costly equipment, maintenance, and down time. You can size and scale your tests based on your level of production.

Receive Photographs and Updates

The best way to monitor your products during the testing process is though digital photography. ATC Test Lab offers high resolution photos at your requested intervals. The use of photographs can help you save money if you need to stop the test early due to product failure or unusual corrosion.

GMW 14872 Cyclic Corrosion

Exposure Testing Chamber at ATC Test Lab

Cyclic Testing

Cyclic Corrosion

Exposure Testing

ATC Test Lab is the Largest Contract Corrosion Test Lab.

- We have over 1200 cubic feet of testing space available.

- Large testing chambers

- Our lab has state of the art equipment to perform the most advanced testing.

- Experienced laboratory technicians conducting your tests.