ACCREDITED TESTING SERVICES

Mixed Flowing Gas

- ASTM B827-97

- ASTM B845-97

- ASTM B810-01a

- IEC 512-11-7

- See More for Complete Tests

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2005

AUTO TECHNOLOGY COMPANY 20026 Progress Drive

Strongsville, OH 44149

Kevin Smith 440 572 7800

MECHANICAL

Valid To: December 31, 2019

Certificate Number: 2563.02

In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to this laboratory to perform tests on the following products or types of products: Aircraft, Automotive, Military, Electronic, Solar Components and Assemblies, Metals, Plastics and Composites.

Test Description and Equipment Parameters

Test Method(s) / Standard(s)

DIN50021

ISO 9227

JIS H8502 Sect. 7.2

JIS Z2371 Sect. 7.2.2

ASTM B368

DIN 50021

Ford FLTM BQ 105-01

GM4476P ² (superseded 2011)

ISO9227

JIS H8502 Sect. 7.3

JIS Z2371 Sect. 7.2.3

Coating Evaluation – Blisters

Coating Evaluation – Corrosion

Coating Evaluation – Corrosion – Creep back

ASTM 610D

ASTM D1654, GM9102P ² (superseded 2012)

Conductivity

ASTM 1125D

ASTM B380

Delphi DX900115

Ford CETP 00.00-L-467

Ford FLTM BI 123-01

Ford FLTM BI 123-02

Ford FLTM BI 123-03

Ford 00.00-L3190

GM9505P Cycles A-O ² (superseded 2012)

GM9511P ² (superseded 2013)

GM9540P ² (superseded 2013)

GM9619P ² (superseded 2012)

GMW14872

GM3172W

Honda 5100Z-SG0-A000

Honda HES D2003

Honda HES D6001-04A

Honda HES D6602 D8N

Hyundai MS 600-66

JASO 609M

Mazda MCT-1M

Mazda MCT-2M

Nissan CCT-I – NES M0158

Nissan CCT-IV – NES M0158

Nissan CCT-V – NES M0158

Renault ECC1 1720D28

SAE 2334J

Toyota TS C5209G

Toyota TS K6532G

Toyota TSH1555G

Volvo VCS 027-114

Volvo VCS 027-1149

Volvo VDA 621-415

VW PV1210

Volvo Std 423-0014

ASTM D2803 Procedures A-C

Honda HES D6501 Sect. 3.16.1

Volvo VDA 1027-141

ASTM D2247

ASTM D5427

Chrysler LP-463PB-09-01

DIN 50017

EIAJ ED-4701/200

Ford FLTM BI 104-01

Ford FLTM BQ 104-02

GM4465P ² (superseded 2015)

GMW14729 (Option A)

Honda 5100Z-SG0-A000

Honda HES D6501 Sect. 3.19

ISO 6270-1

MIL-STD-810G Method 507.5

SAE-AMS-STD 753C Method 101

Toyota TSH 1505G

W3044

Temperature and Humidity¹

-70 °C to 180 °C; 10 % RH to 95 % RH

W4700 (label compatibility)

ASTM 1293D

pH

ASTM 1293D

Rating of Electroplated panels

ASTM B537

Salt Spray (fog)¹

ASTM B117

ASTM C1503 – 20% ASTM D5894-05

ASTM E11

ASTM G85 Annex 1

ASTM G85 Annex 2

ASTM G85 Annex 3

ASTM G85 Annex 4

ASTM G85 Annex 5

Chrysler LP-463PB-10-01

Delphi DX551200 Sect 4.3, 4.3.2

Delphi DX551300 Sect 4.3, 4.3.2 DIN 50021

EIA-364-26B

Ford FLTM BI 103-01

GM4298P ² (superseded 2011

GMW3044 Sect 3.4

GMW3235 (Method A)

GMW3286

GMW4700 Sect 3.4

Honda 5100Z-SG0-A000

Honda HES D6001 Sect. 4.3

Honda HES D6501 Sect. 3.15.1

Honda HES D6501 Sect. 3.15.2

IEC 68-2-11

IEC 82/576 Sect. 7

IEC 60068-3-5, 6, 7

IEC 61215

IEC 61646

IEC 61730-2

IEC 62108

ISO 7253

ISO 9227

JASO M610

JIS H8502 Sect. 7.1

JIS Z2371

MIL-STD-810G Method 509.5

Nissan NES M0140

Renault D17-1058/–J

Renault D17-1686/–E

RTCA/DO-160D

SAE 1756J

Toyota TSH1552G

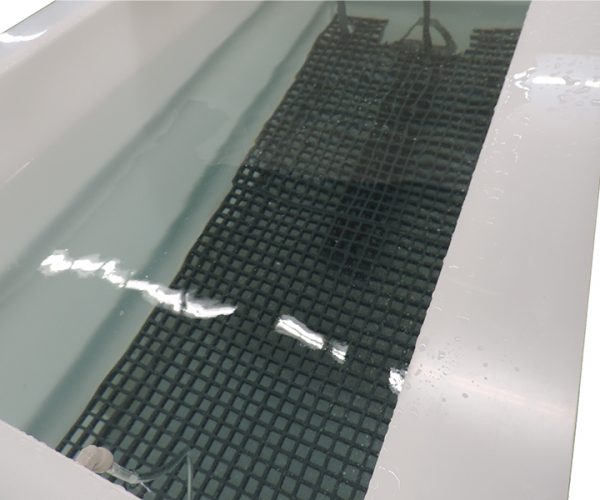

Salt Water Immersion

Chrysler MS-PB1-2

SO2¹

ASTM G87

DIN 50018

ISO3231

ISO6988

Temperature¹

ASTM D1429 Method D

Ford WSS-M2P177-A1-5 Sect. 3.5.7

Ford WSS-M2P184-A Sect. 3.6.7 & 3.6.8 Honda HES D6001 Sect. 4.4.1

Honda HES D6501 Sect. 3.20.1

Honda HES D6501 Sect. 3.20.2

MIL-STD-810G Method 501.5, 502.5, 507.5 Toyota TSH 1551G Sect. 9

Thermal Shock¹

Ford WSB-M1P83-B1 Sect. 3.8.2

GM4372M Sect. 3.5.2 ² (superseded 2011)

Honda HES D6001 Sect. 4.4.4

Honda HES D6501 Sect. 3.29

Toyota TSH1551G

Water Immersion

ASTM 870D

Ford FLTM BI 104-01

GM3628M (3.12) ² (superseded 2015)

GM4466P ² (superseded 2015)

GM9514P ² (inactive 2011)

Honda 5100Z-SG0-A000

Honda HES D6501 Sect. 3.18

Honda HES D6501 Sect. 3.37

ISO 2812-2

Mazda MES MN601 (13)

Toyota TSH 1551G

¹ Also using customer specific test methods utilizing any combination of test equipment parameters listed above.

² This laboratory’s scope contains withdrawn or superseded methods. As a clarifier, this indicates that the applicable method itself has been withdrawn or is now considered “historical” and not that the laboratory’s accreditation for the method has been withdrawn.

Accredited Laboratory

AUTO TECHNOLOGY COMPANY

Strongsville, OH

for technical competence in the field of

Mechanical Testing

This laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2005 General requirements for the competence of testing and calibration laboratories. This laboratory also meets the requirements of any additional program requirements in the Mechanical field. This accreditation demonstrates technical competence for a defined scope and the operation of a laboratory quality management system

(refer to joint ISO-ILAC-IAF Communiqué dated April 2017).

Presented this 25th day of May 2018.

President and CEO

For the Accreditation Council Certificate Number 2563.02 Valid to December 31, 2019

For the tests or types of tests to which this accreditation applies, please refer to the laboratory’s Mechanical Scope of Accreditation.